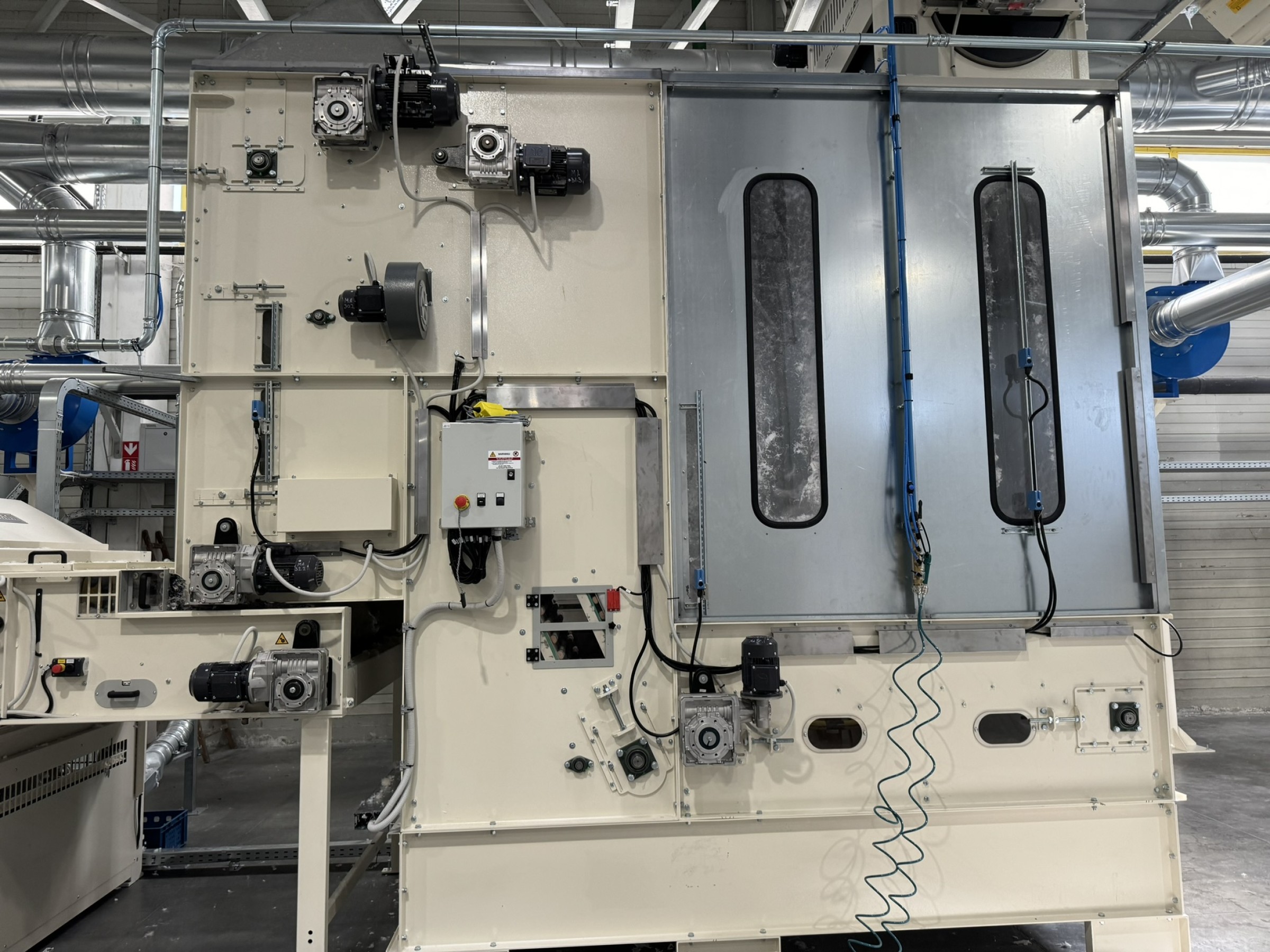

COMPLETE ANDRITZ / LAROCHE RECYCLING LINE

Manufacturer: ANDRITZ-LAROCHE

Year: 2023

PROPOSAL NO.6408-RECY

(COMPLETE) ANDRITZ / LAROCHE RECYCLING LINE

Year 2023

Working Width 2000 MM

Scope of supply

ONE TEARING UNIT

16.2.1 ONE CUTTING AND STORAGE UNIT

Qty Description

1 ONE (1) LONG FEEDING CONVEYOR IN 0.5 M WORKING WIDTH

1 ONE (1) GUILLOTINE CUTTER TYPE CT60N with long feeding conveyor to permit later on to put a ROBOT instead of the long feeding conveyor mentioned above and also with dedicated feeding conveyor to be able to put later on a Alutron Metal detector on this conveyor

1 ONE (1) TRANSFER CONVEYOR type CO25

1 ONE (1) GUILLOTINE CUTTER TYPE N60 with classical feeding conveyor

1 ONE (1) CONVEYOR WITH HEAVY PARTICLES TRAP

1 ONE DELIVERY FAN VT560TRD

1 ONE CONDENSER TYPE FC 1400 WITH DEDUSTING FAN VT450

1 ONE OILING SYSTEM IN ROTARY TRUNK with 1000 liters tank

1 ELECTRICAL EQUIPMENT for pos 16.2.1

16.2.2 ONE BLENDING BOX

Qty Description

1 ONE INPUT FAN VT560TRD

1 ONE BLENDING BOX TYPE SM 3900/20 with dedusting fan VT450

(up to 230 m3 of raw material and for storage/blending of raw material capacity up to 10T)

16.2.3 ONE "EXEL 2000"/2 PICKER UNIT

Qty Description

1 ONE INPUT FAN VT560TR

1 ONE CONDENSER TYPE FC1400 WITH DEDUSTING FAN VT450

1 ONE BALE BRAKER TYPE OBT 2000 WITH DELIVERY CHUTTE FEED

1 ONE CONDENSER TYPE FC 1400 WITH DEDUSTING FAN VT450

1 ONE DELIVERY CHUTTE FEED WITH 2 DELIVERY ROLLERS

1 ONE "EXEL 2000"/2- WASTE PICKER UNIT WITH 2 OPENING AND SORTING UNITS AND

ONE CONDENSING SECTION WITH ONE COLLECTING AND LATTERAL CONVEYORS

FOR UNOPENED BITS

1 ONE CLEANING UNIT FOR UNOPENED BITS With 2 FANS TYPE VT 360 AND ONE CYCLONE

1 ONE DELIVERY FAN VT560TRD

16.2.4 ONE "EXEL 2000"/5 TEARING UNIT

Qty Description

1 ONE INPUT FAN VT560TR

1 ONE CONDENSER TYPE FC1400 WITH DEDUSTING FAN VT450

1 ONE BALE BRAKER TYPE OBT 2000 WITH DELIVERY CHUTTE FEED

1 ONE CONDENSER TYPE FC 1400 WITH DEDUSTING FAN VT450

1 ONE DELIVERY CHUTTE FEED WITH 2 DELIVERY ROLLERS

1 ONE "EXEL 2000"/5- WASTE PICKER UNIT WITH 5 OPENING AND SORTING UNITS AND

4 CONDENSING SECTION WITH ONE COLLECTING AND LATTERAL CONVEYORS FOR

UNOPENED BITS

1 ONE CLEANING UNIT FOR UNOPENED BITS WITH 2 FANS TYPE VT 360 AND ONE CYCLONE

1 ONE INTEGRATED SHARPENER FOR THE PINS ON OPENING CYLINDERS

1 ONE DELIVERY FAN VT560TRD

16.2.5 ONE ELECTRICAL CONTROL PANEL

Qty Description

1 ELECTRICAL CONTROL PANEL for the above equipment mentioned in pos

16.2.2.+16.2.3+16.2.4 with inverters for EXEL 2m picker unit and EXEL 2m tearing unit:

With 7 x 75 kw AC Inverters + all AC inverters for all fans type (VT560, VT450, VT360)

PLC and Touch screen from Siemens

16.2.6 VERTICAL BALING PRESS

Qty Description

1 ONE CONDENSER TYPE FC 1400 WITH DEDUSTING FAN VT450

1 BALING PRESS NEW GENERATION TYPE DB 100/6 –

with manual packing and tying with automatic ejection of the bales, including

• Box dimension: 72 x 114 x 110 cm

• Ram Cylinder.

• Pressing Force: 100 Tons.

• Hydraulic power unit.

• Oil tank & pump.

• The press has 6 bales/hour capacity. (bale up to about 250-280 kg/bale)

• The bale will be tied by 8 polyester straps or steel wires manually.

• 4-meter automatic conveyor.

• Air-oil cooler is included.

• Platform included

• weighing unit

• One printer

• Safety barriers

• Electrical Cabinet

16.2.7 FILTRATION

Qty Description

1 AUTOMATIC FILTRATION – including:

Capacity: up to 90 000 m3/h

• pre-filter with suction nozzle

• finishing drum filter with suction nozzles

• cyclone for heavy dust

• cyclone system for fine dust

• blower for heavy dust

• blower for fine dust

• internal piping

• electrical equipment

16.2.8 ADDITIONAL EQUIPMENTS: SPARE PARTS, SPARE OPENING CYLINDERS

Qty Description

1 ONE (1) SET OF EMERGENCY SPARE PARTS

(For a value of FCA ANDRITZ Laroche Plants in France € 35 400 )

1 ALL LAYOUT AND ASSEMBLING DRAWINGS FOR ONE (1) SET OF PIPES FOR 550 m

long pipes for this line according to customer’s Building but without the pipes

1 ONE (1) SPARK DETECTOR FROM TEARING MACHINE TO BALE PRESS w/ EXTINGUISHER

1 ONE (1) ALUTRON METAL DETECTOR FOR THE GUILLOTINE CUTTER TYPE CT60N

1 ONE (1) PNEUMATIC BYPASS AT THE OUTPUT OF THE THIRD OPENING CYLINDER OF

THE EXEL TEARING UNIT

(in order to by-pass the 2 last Opening cylinders, with extra delivery trunck, higher

supports for the EXEL tearing line and extra electrical equipment)

1 TWO (2) SPARE EXEL OPENING CYLINDERS IN 2M WIDTH

with bearing and set of pins lags already mounted.

(in order to get maximum capacity for nonwoven applications)

1 ONE (1) OILING SYSTEM IN PIPES with 500 liters tank AND SIX (6) BY-PASS TYPE DFL

for piping Dia. 300 mm

For spinning application, with the simple blending box (refer Pos.16.2.2) after the EXEL

2000/2 Picker (refer Pos. 16.2.3)

Contact for Pricing

Share